High measurement quality

- ristretto! supports

analog and digital, factory-calibrated TSic precision

temperature sensors. Accuracy exceeds Pt100 Class B.

- ristretto! offers

significantly more measurement resolution and calibrated

accuracy than most other PID controllers by utilizing 24bit ADC

circuits and calibrated digital sensors on supported modules

- Multiple sensors may be

connected simultaneously, for example a boiler sensor, a cup

sensor, a PCB sensor and a reference sensor

- ristretto!

supports pressure sensors and flow meters to measure pressure,

volume and flow rate

Ultimate temperature

control (PID)

- Dual channel PID

function for up to two heating elements (two boilers or one

boiler plus one electronically heated brew group)

- PID parametrization:

Different PID configurations can be used during different states

of the machine (idle phase, shots)

- "Ramp & Soak" feature

for programmed heating, independent of measurements, to

manually optimize the brew temperature during espresso shots

- Feed-forward control

based on flow meter measurements

- Dual setpoints for normal

control and eco mode

- Setpoints can be changed in

steps of 0.1°C. The internal resolution is 0.0625°C

- Automatic determination of

PID configuration by auto tuning program

- Advanced PID configuration

options such as digital filtering and integral wind-up limiting

- Configurable Standby

feature and ECO mode to conserve energy

Useful programs

- Automatic determination of

PID configuration by auto tuning program

- Calibration program for

analog sensors

Grinder control

- Grind timer: ristretto!

can run a grinder for a programmed time for single or double

shots

Clock and timer

- Clock and weekday timers

to turn the heating elements on and off automatically

- Alarm clock function

Information at your

fingertips

- Three lines of output on a

LCD display convey status information: temperatures, setpoints,

heat output, pressure (in bar), shot volume (in ml) etc.

- Comfortable text menus

instead of cryptic numbers (most PID controllers only have

7-segment numerical displays)

- Backlight, brightness and

contrast are controlled by the firmware1

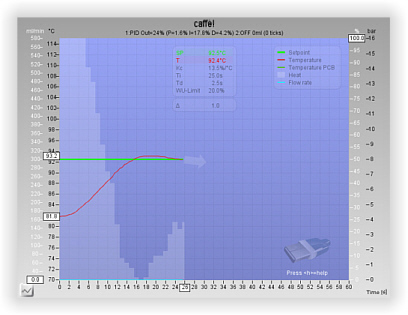

- ristretto!

continuously transmits measurements to a PC connected by USB or

Bluetooth where they can be viewed on a Virtual LCD or as

real-time plots. Visual and numeric presentation of live PID

data permits unprecedented insight into PID configuration

- PID controllers switch

power rapidly but with ristretto!, this will not cause a

randomly flickering boiler light because ristretto!

controls the boiler lamp independently to convey useful state

information

- Adjustable brightness of

PID lamp (LED)

Real-time plots on PC |

Monitoring and safety

features

- Monitoring of water

filter's age and liter throughput

- Water hardness

calculator and scale buildup monitoring

- Backflushing reminder

- Safety functions monitor

the on-times of heating elements and sound an alarm if operator

error is detected

Invisible

- Support for internal

installation without LCD display (remote configuration by

computer via Virtual LCD program)

- Instead of an obtrusive

display, a discreet toggle switch can be installed as

temperature selector.

Training functions

- Shot timer to make

by-the-rules espresso with perfect 25s timing

- Ready-beep signals when the

machine is thoroughly heated up

1: If supported by the

hardware. Some features depend on the microcontroller module and

are not available on all supported platforms. For example,

easy-Kit modules do not support analog temperature sensors. |