High measurement quality

- leva! supports

temperature sensors, pressure sensors, flow meters and Bluetooth

LE scales to measure and control temperature, pressure, volume,

flow rate and weight.

- leva! supports

digital factory-calibrated TSic precision temperature sensors.

Accuracy exceeds Pt100 Class B.

Ultimate temperature

control with PID algorithm

- Dual channel PID

function for up to two heating elements, for example two

boilers or one boiler and one electronically heated grouphead

- Temperature setpoints can

be changed in steps of 0.1°C

-

Different PID configurations can be used during different

states of the machine (warming up, idle phase, shots)

- Two temperature sensors may

be connected simultaneously, for example a boiler sensor and a

grouphead sensor

- Virtual temperature

sensors: Two sensors can be combined into a virtual

sensor, for example to take the temperature of the grouphead into

account.

- Ramp & Soak feature for

programmed heat output during shots to optimize the 25s brew

temperature curve

- Feed-forward temperature

control based on flow meter measurements

- Automatic determination of

PID configuration by auto-tuning program

- Advanced PID configuration

options such as digital filtering and integral wind-up limiting

- Configurable Standby

Mode and ECO Mode to conserve energy

Electronic pump power

control

- Electronic pump power

control for vibration pumps with feedback from a pressure sensor, with nearly stepless power control. This feature gives you

high-quality pressure profiling, for example gradually falling brew pressure

(= lever-style pressure profile).

Example

video

Example

video

- Paddle support. Use

an electronic lever or the rotary encoder of the display to

control brew pressure manually, on the fly, at any moment in the

shot

- Real preinfusion:

Variable, programmable preinfusion with the desired pressure curve

- Flow tracking: The

firmware can lock the flow rate towards the end of your shots

- Flow rate control at the

beginning of shots (before pressurization)

Pressure profiling control loop with

pressure sensor |

Information at your

fingertips

- Four lines of output on an

OLED display (optional) convey useful information: Temperatures, setpoints,

heat output, pressure, shot volume, shot weight etc.

- Comfortable text menus

instead of 7-segment numerical displays:

- OLED brightness controlled

by firmware

- PID controllers switch

power rapidly, which normally leads to a flickering boiler lamp.

With leva!, you

will not have to endure a flickering lamp because it offers a

lamp replacement in form of a firmware-controlled, white,

dimmable LED to convey useful state information.

- Automatic dimmable

grouphead illumination

Apps for Android, Windows,

Linux and Mac OS X

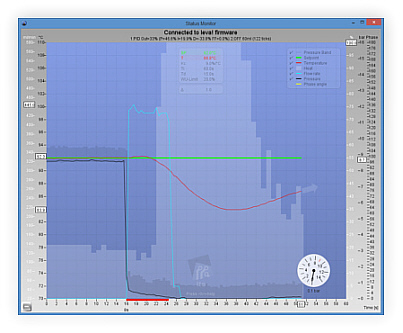

- leva!

continuously transmits measurements to a PC or Android device

connected by WLAN, where they can be viewed as real-time plots

in apps. Visual and numeric presentation of live data

permits unprecedented insight.

- The apps let you use your

mobile devices and computers as Virtual Display if you install the hardware without

a physical display

Real-time plots of live data on your

computers (Windows, Linux or MacOS X) and Android devices

App running on a tablet

(optional) on an espresso machine

|

Dosing, Descaling and

Flushing

- Dosing feature for

dispensing programmed amounts of product with the desired

flow rate or pressure profile.

leva! supports dosing by time, by water volume (flow meter)

or by weight (gravimetric dosing with Bluetooth scale). Supports Felicita

Arc, Skale 2 and Eureka Precisa scales.¹

- Brew ratio calculator

- Automatic cup detection:

Assign doses and/or pressure profiles to cups identified by

weight

- leva!'s warm-up program

can drastically reduce warm-up time by flushing hot water

through the machine

- Customizable

descaling program

Gravimetric dosing with wireless

Bluetooth scales. Left to right:

Eureka Precisa (original version)¹, Skale 2,

Felicita Arc |

Dual boiler support

- Support for steam boiler

on/off switch

Monitoring and safety

features

- Monitoring of water

filter's liter throughput

- Water hardness

calculator and limescale buildup monitoring

- Backflushing reminder

- Safety functions monitor

the on-times of heating elements, pump and valve and turn off

the machine or sound an alarm if a problem is detected.

Invisible

- Support for internal

installations without display. Wireless configuration by

computers/Android devices .

- Instead of a full display

module, a hidden rotary encoder can be installed as temperature

selector.

Training functions

- Acoustic and optical

(display) shot timer to make by-the-rules espresso with perfect

25s timing

- Ready-beep signals when the

machine is thoroughly heated up

1: Note that a non-Bluetooth version of the Eureka Precisa exists. Be careful when buying.

|