High measurement quality

- caffè! supports

analog and digital, factory-calibrated TSic precision

temperature sensors. Accuracy exceeds Pt100 Class B.

- caffè! offers

significantly more measurement resolution and accuracy than most

other PID controllers by utilizing 24bit ADC circuits1

and calibrated digital sensors

- Multiple sensors may be

connected simultaneously, for example a boiler sensor, a cup

sensor, a PCB sensor and a reference sensor

- caffè! supports

pressure sensors and flow meters to measure and control

pressure, volume and flow rate

Ultimate temperature

control (PID)

- Dual channel PID

function for up to two heating elements (two boilers or one

boiler plus one electronically heated brew group)

- PID parametrization:

Different PID configurations can be used during different states

of the machine (warming up, idle phase, shots, steam)

- "Ramp & Soak" feature

for programmed heating, independent of measurements, to

manually optimize the brew temperature during espresso shots

- Feed-forward control

based on flow meter measurements

- Triple setpoints for normal

control, steam and eco mode

- Setpoints can be changed in

steps of 0.1°C. The internal resolution is 0.0625°C

- Automatic determination of

PID configuration by auto tuning program

- Advanced PID configuration

options such as digital filtering and integral wind-up limiting

- A dedicated steam sensor

can be installed to improve steam control

- Configurable Standby

feature and ECO mode to conserve energy

Electronic pump power

control

- Electronic pump power

control for vibration pumps with feedback from a pressure sensor, with

nearly stepless power control. This feature gives you

high-quality pressure profiling, for example gradually falling brew pressure

(= lever-style pressure profile).´

- Paddle support: Use

an electronic lever to control brew pressure manually, on the

fly, at any moment in the shot

- Real preinfusion:

Variable, programmable preinfusion with desired pressure curve

- Flow rate control at the

beginning of shots (before pressurization)

Pressure sensor |

Useful

programs

- Doser feature for

dispensing programmed amounts of water to group or wand with

desired flow rate

- Warm-up program can

drastically reduce warm-up time by flushing hot water through

the machine

- Descaling program

- Calibration program for

analog sensors

Dual-boiler support

- Support for steam boiler

on/off switch

- Support for auto-fill pump

and external auto-fill controller (caffè! monitors the

signal of the auto-fill controller)

Grinder control

- Grind timer: caffè!

can run a grinder for a programmed time for single or double

shots

Clock and timer

- Clock and weekday timers

to turn the machine on and off automatically

- Alarm clock function

Information at your

fingertips

- Three lines of output on a

LCD display convey status information: temperatures, setpoints,

heat output, pressure (in bar), shot volume (in ml) etc.

- Comfortable text menus

instead of cryptic numbers. Most PID controllers only have

7-segment numerical displays.

- Backlight brightness and

contrast are controlled by the firmware1

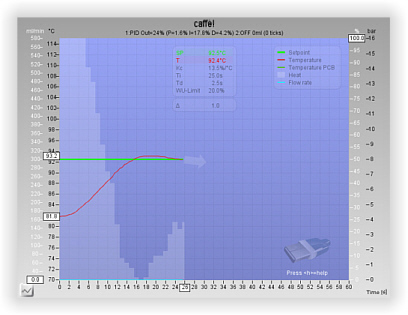

- caffè! continuously

transmits measurements to a PC connected by USB or Bluetooth

where they can be viewed on a Virtual LCD or as real-time plots.

Visual and numeric presentation of live PID data permits

unprecedented insight into PID configuration

- All shot data is automatically

recorded on dataflash memory for later inspection

- PID controllers switch

power rapidly but with caffè!, this will not cause a

randomly flickering boiler lamp because caffè!

controls the lights independently to convey useful state

information

- Adjustable brightness of

PID lamp (LED) and lamps in switches (LEDs)

1

Real-time plots on PC |

Monitoring and safety

features

- Monitoring of water

filter's age and liter throughput

- Water hardness

calculator and scale buildup monitoring

- Backflushing reminder

- Safety functions monitor

the on-times of heating elements, pump and valve and turn off

the machine if operator error is detected.

Invisible

- Support for internal

installation without LCD display (remote configuration by

computer via Virtual LCD program)

- Instead of an obtrusive

display, a discreet toggle switch can be installed as

temperature selector.

Training functions

- Shot timer to make

by-the-rules espresso with perfect 25s timing

- Ready-beep signals when the

machine is thoroughly heated up

- Automatic dimmable

grouphead illumination

1: If supported by the

hardware. Some features depend on the microcontroller module and

are not available on all supported platforms. For example,

faustino modules do not support adjustable display brightness and

not all modules have a 24bit ADC. |